Rotary jetting unit launches Krones into the lead

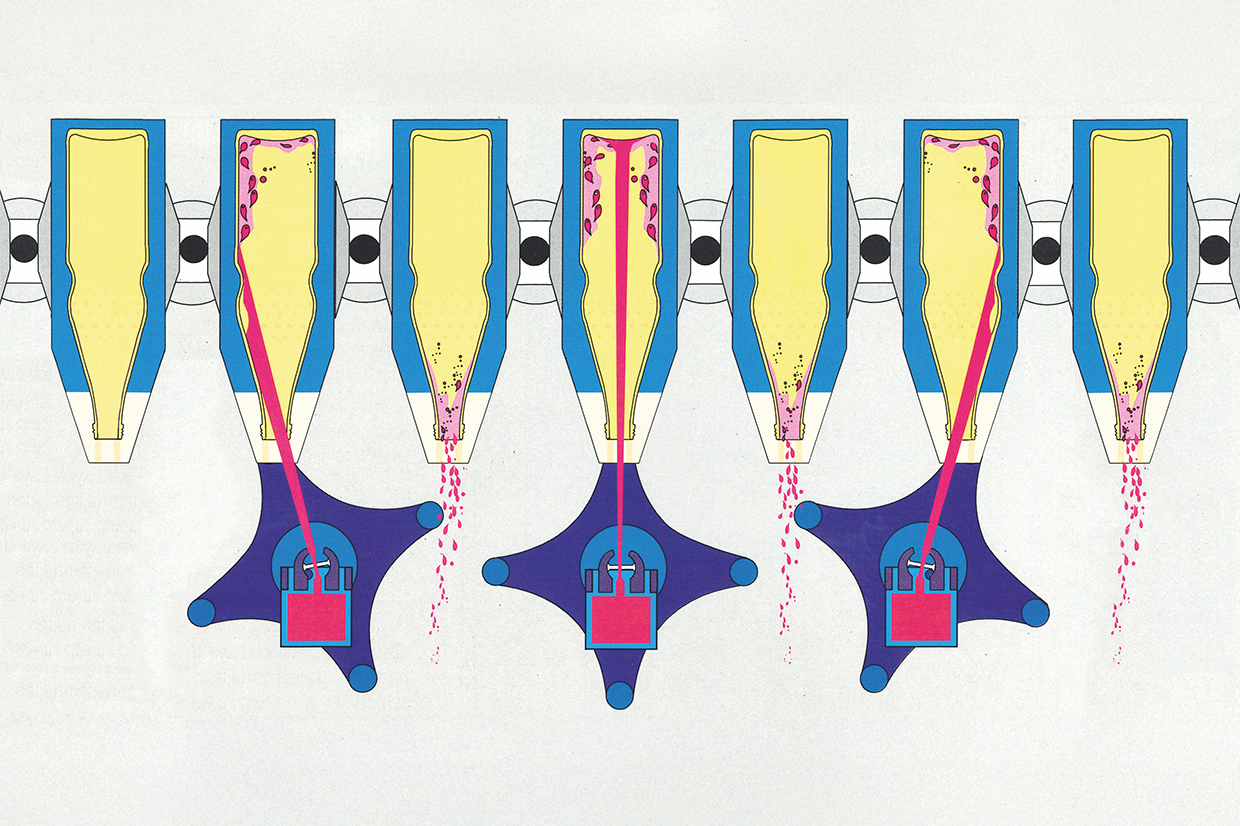

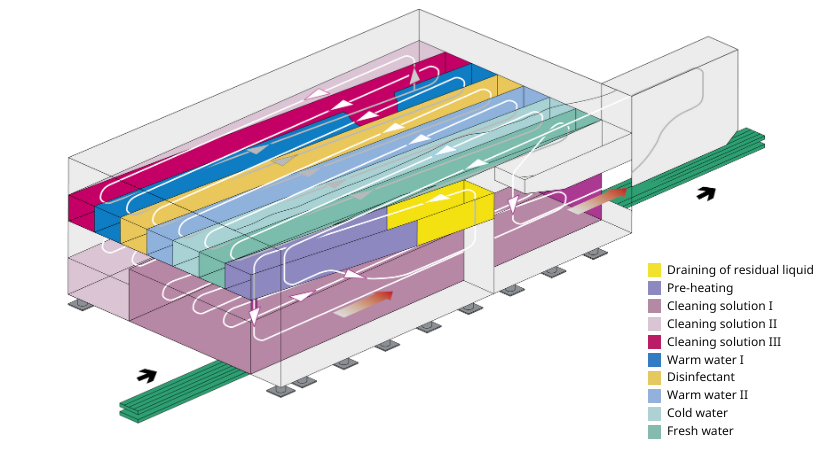

However, it would be several years before Krones became the leader in bottle washing technology, a milestone we would reach by a real stroke of luck. It started with a technical problem that plagued nearly every bottle washer at the time: Like today, bottles passed through multiple immersion baths and spray zones for treatment with caustic and water. The challenge was that dirt particles and bits of labels would, time and again, clog the nozzles that were meant to spray the inside of the bottles. Manufacturers experimented with small rods, brushes and other options to clear the nozzles while the machine was running – but none of the solutions passed muster. There was only one method that really worked, and it was patented: a rotary jetting unit that was self-cleaning as the rotation of the tube itself caused the liquid to be sprayed through the nozzles in alternating directions.

Matthias Wahl joined the Krones Patents Department in 1986 and recalls: “Nobody could get around that patent. It was hard to sell a machine at a reasonable price without this solution. We had already done extensive research. Of course, there was no such thing as online research back then. We had to go to Munich, where we would spend hours in the search room of the Patent Office, poring in vain over old documents dating back to the German empire.”

A patent is everything

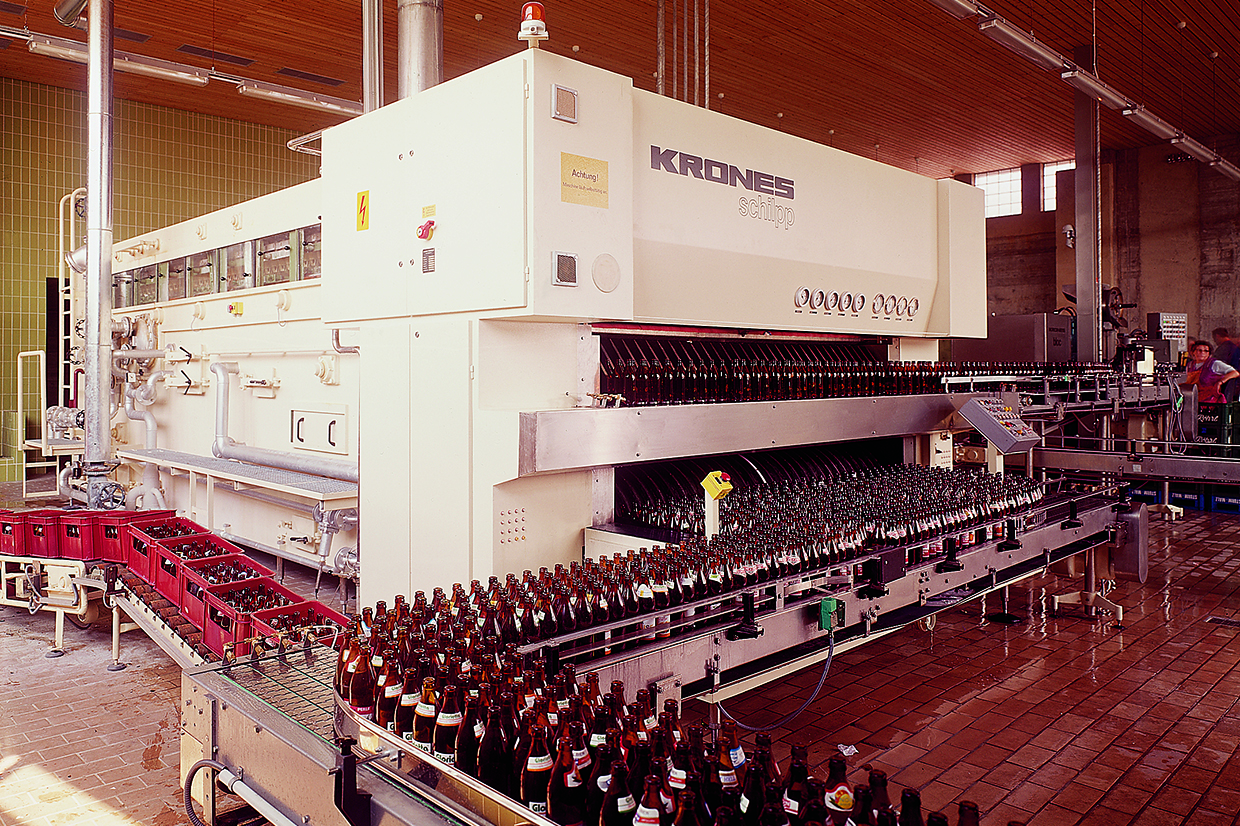

That was the situation when Hermann Kronseder received an offer to buy the Flensburg-based bottle-washer manufacturer Zierk. It turned out that the company had a licence to this very patent. Wahl recalls the excitement: “I still remember how Mr. Kronseder came into the office holding a sheet of paper and said to Hansjörg Halbo, my boss at the time: Take a look at this! And please tell me if it will stand up to scrutiny.” And that’s how, in 1988, Krones not only gained another plant, way up in the north of Germany, but also got catapulted into the Champions League of bottle-washer manufacturers. From then on, business in this area really took off because Krones had a solution that was in high demand on the market.