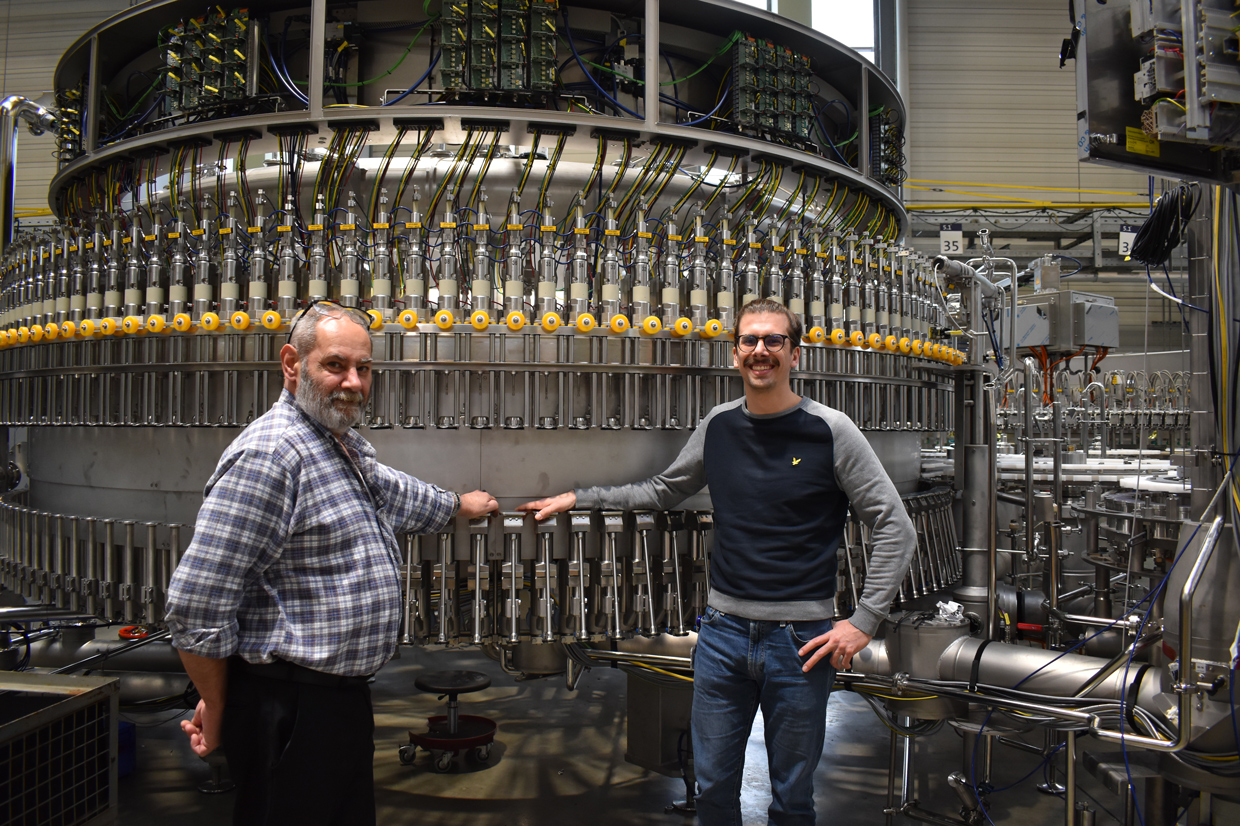

When the skilled machine fitter is asked about his work, the passion just pours out of him. He completed his vocational training at Krones way back in 1979 and has now been working in Filling Technology for 40 years. Over that time, he has been through quite a number of stages, whether as an apprentice in Labelling Technology or during his military service, when he built his first filler as a holiday job. He then joined the company full-time as a mechanic in Filling Technology. “I very quickly discovered that Filling Technology is with you for life,” he recalls. He has lived by this conviction ever since, working his way up from fitter to foreman, junior to senior master craftsman and, finally, head of department. In 2020 he started looking after technical coordination, supporting projects from receipt of the order to delivery.

“He knows everything!”

Piendl still feels at home in the plant. He has a story ready for every machine that is being built here, knowing them like the back of his hand. From the Modulfill to the Contipure, the complex processes in the machines are part and parcel of his everyday life. He has acquired this expertise over decades, and his experience makes him a trusted point of contact for his colleagues. “He knows everything and has done everything”, says Sebastian Wittl, a product manager in Filling Technology. “I really value the experience that Peter shares with us and that we can learn from him.”