“Keep line stops to a minimum” is the watchword for the project being jointly implemented by Krombacher and Krones. After all, the last thing the brewery needs right now is lengthy downtimes, as demand for its beers, beer-based mixed drinks and soft drinks remained high throughout 2024 despite the German beer market shrinking.

In order to prepare itself for future challenges, Krombacher decided in 2021 to upgrade part of its existing machines, since some of its lines had already been providing continuous service for over 30 years.

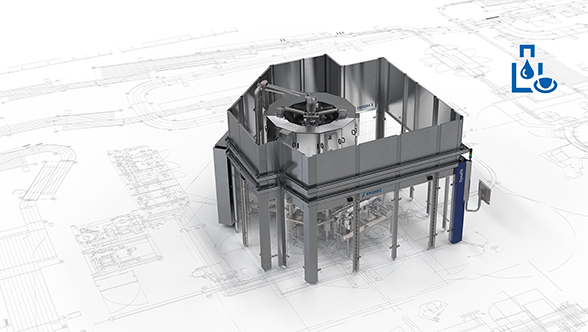

Kickoff: joint planning of the factory-restructuring project

The brewery then contacted Krones with its requirements and commissioned the factory-planning team to draw up the best possible strategy for the upcoming mammoth project of replacing machines in no less than four lines. The team soon realised that this task called for a radical rethink of all existing production sequences. To give but two examples: One empties palletiser had previously served two lines but in future each line is to get its own system. And certain process steps that used to be performed by hand are to be automated. The overarching purpose is clear: ensuring efficient production sequences. “Master planning is aimed at establishing plant and factory structures that will boost the brewery’s success now and in future. It basically involves mapping out consistent guidelines for plant development that can be adapted to suit various market requirements. Each of the project’s three parts – analysis, target formulation and evaluation – was drawn up in detail in conjunction with Krones and together, they provide a solid basis for implementing the individual construction stages,” explains Rainer Bub, head of the project management department at the Krombacher Brewery.