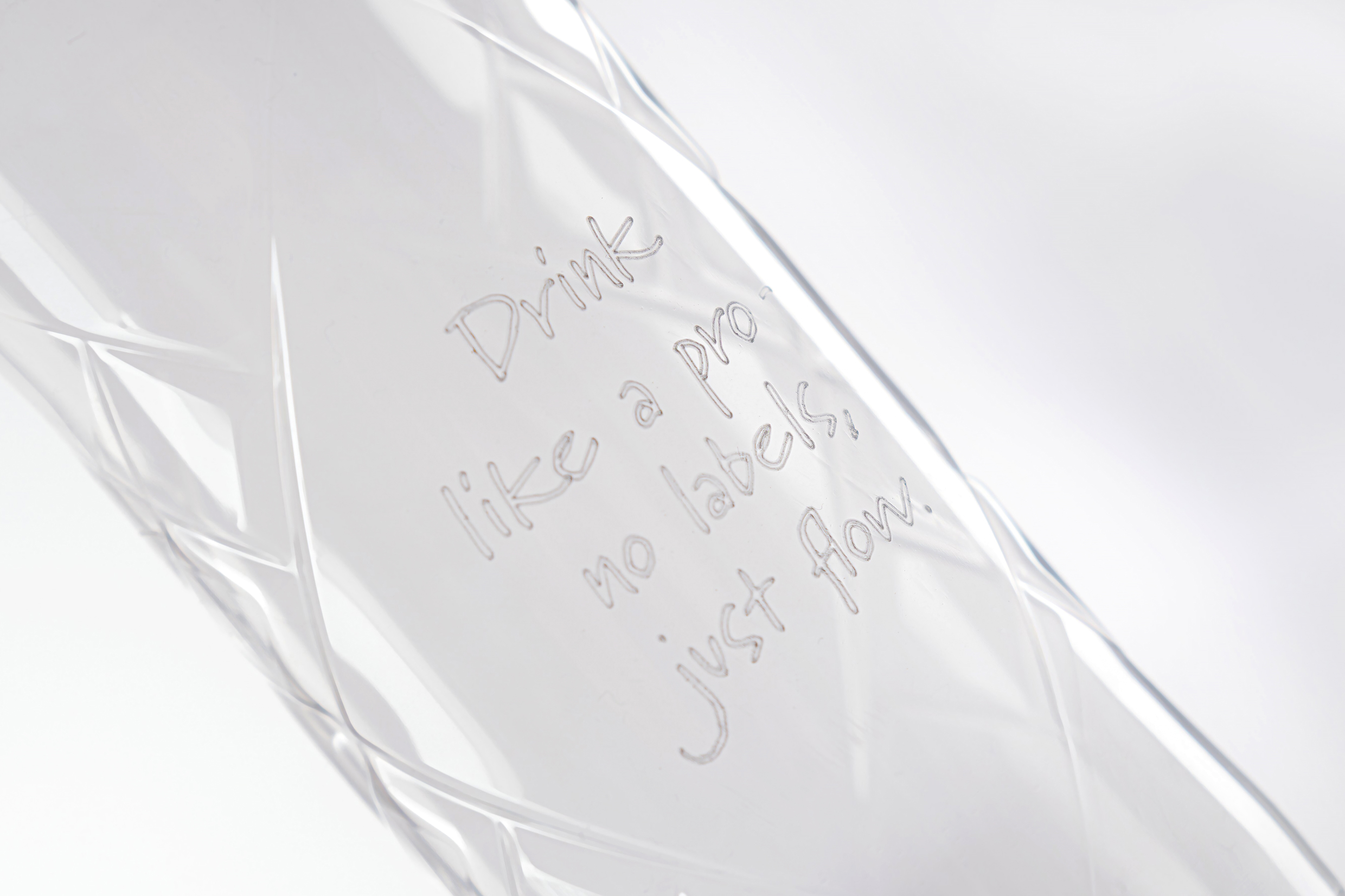

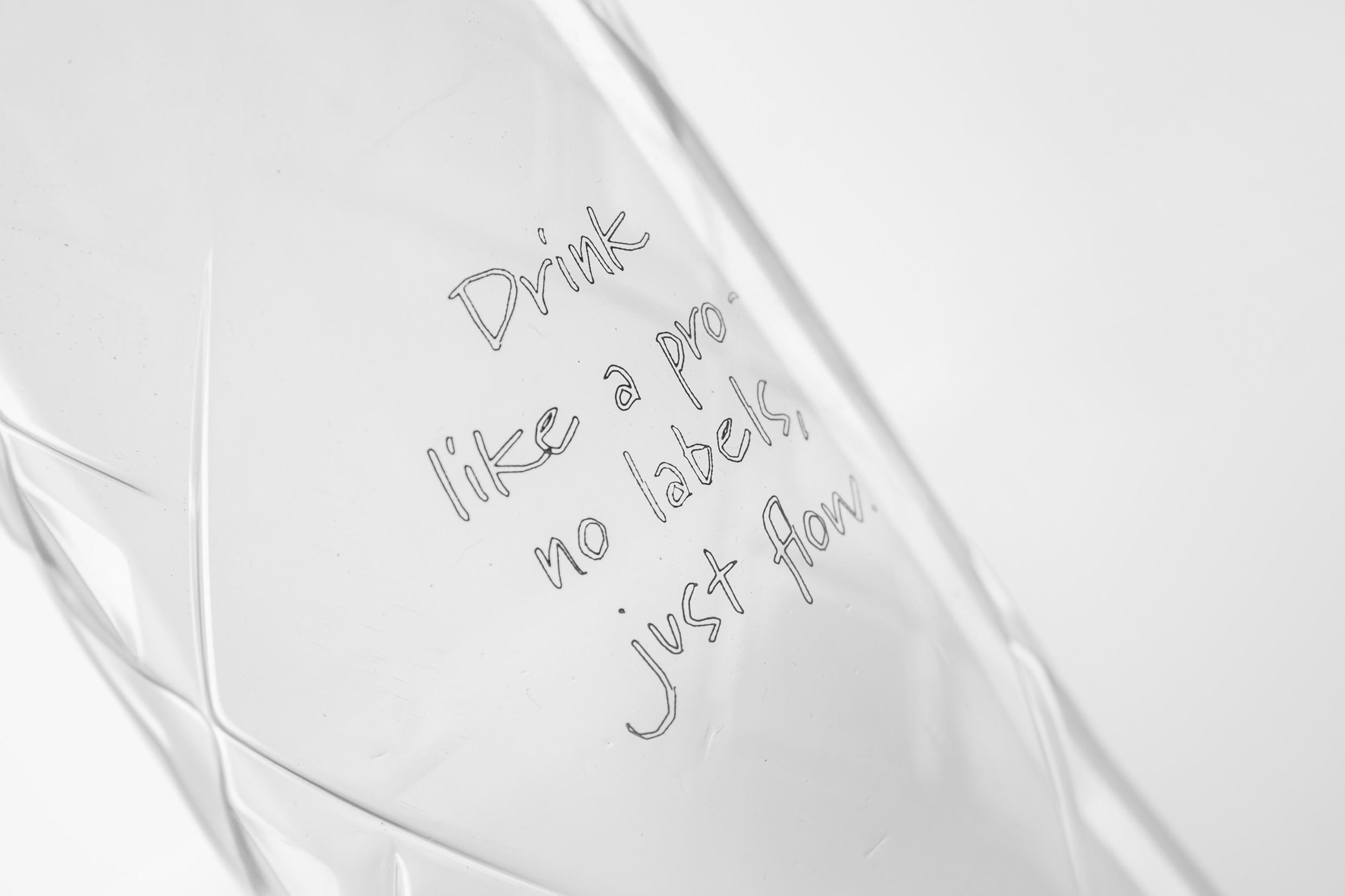

Although they may seem tiny among the massive machines in our exhibition hall, many visitors can’t take their eyes off the bottles on display in our decoration technology area. They are picking them up, turning them over in their hands and running their fingers over the surfaces, comparing the different bottles. What’s got them so enthralled? These containers bear no traditional labels – and yet they have everything that beverage packaging needs. Thanks to two innovations from Krones’ decoration technology team: DecoBeam and INKpression.

Modern packaging doesn’t have to include a traditional label. Krones is presenting two innovations at drinktec 2025 that show how beverage bottles and other containers can be decorated in an entirely new and material-saving way.

Innovation No. 1: Lasers instead of labels

With DecoBeam, Krones offers a trailblazing solution for putting content directly onto PET bottles – even 100 percent recycled PET. Instead of using printed labels, a laser etches all relevant information such as net fill volume, ingredients, best-before date and any design elements directly onto the PET bottles. The benefits are clear: The packaging uses less material, can be completely recycled, and gives consumers a better look at the refreshing drink inside!

The marking is accomplished using one of two different laser technologies, depending on the application: A CO₂ laser provides a whitish color impression while a fiber laser gives the marking a black tint. Besides text, the system can also apply logos, graphics and other design elements.

Innovation No. 2: A label that consists of nothing but ink

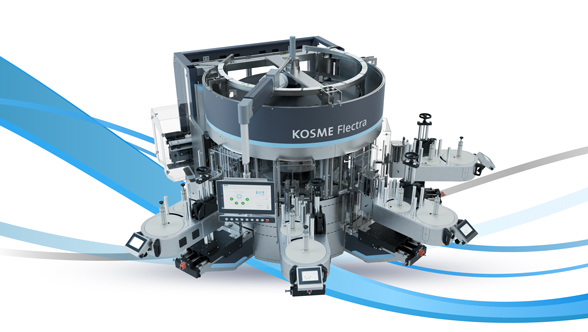

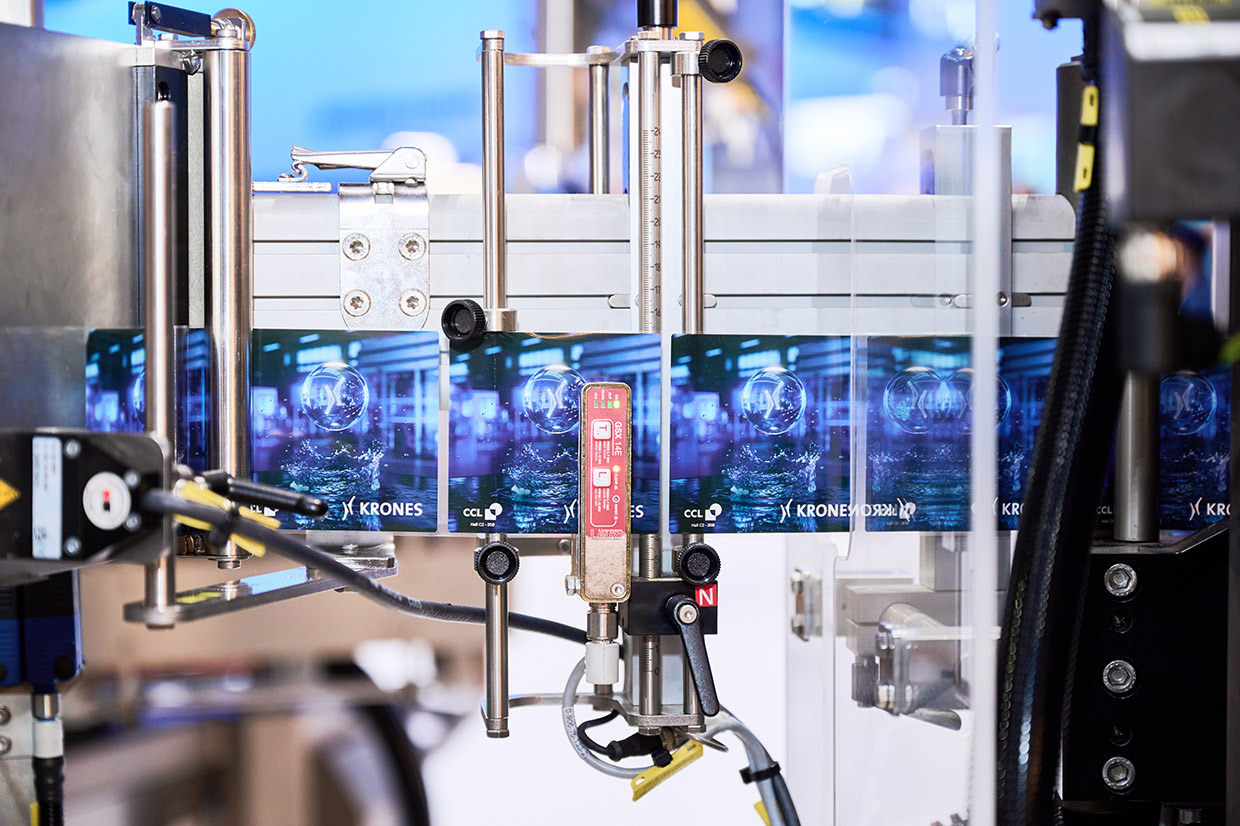

INKpression directly transfers ink onto containers. What makes this system so special is that it doesn’t use a conventional printing process. Much like a self-adhesive label, the finished design is simply peeled off a carrier material and transferred onto the container in one piece. The result is a high-quality container decoration that immediately catches the eye.

Whether for glass bottles or PET containers, INKpression labels are giving beverage producers an exceptional degree of freedom in their product design and adhere perfectly to the surface of the container. What’s more, they’re resource-saving. Because they consist of nothing but ink, they use less material and generate less waste.

And although INKpression is a completely new way of decorating containers, the technology behind it has been proven in the field many times over. That is, it uses a labelling station from Krones’ standard portfolio that has been modified specially for this purpose.

Two technologies, twice the innovative vigor

With DecoBeam and the INKpression labelling station, Krones offers two innovative technologies that intelligently unite sustainability and design. They both reduce the amount of material used, improve recyclability and put the product center stage – for packaging that does more than “just” look good.